Ultrasonic sensors have many advantages for measurement and calculations. With a diverse range of applications, it has been using in different industries such as food industries, automotive, and health care for level measurements. One of the great attractions of the ultrasonic sensor is that its functionality is pretty simple.

Measuring liquid levels in the large cylinders and tanks can be a difficult task. In fact, most of the time, you cannot get the reliability and accuracy of the level, especially in the case of wastewater. The suspended solids and contamination in such water make it difficult to get an accurate measurement. In such cases, the best option is to use an ultrasonic sensor.

An advanced technology for level measurement

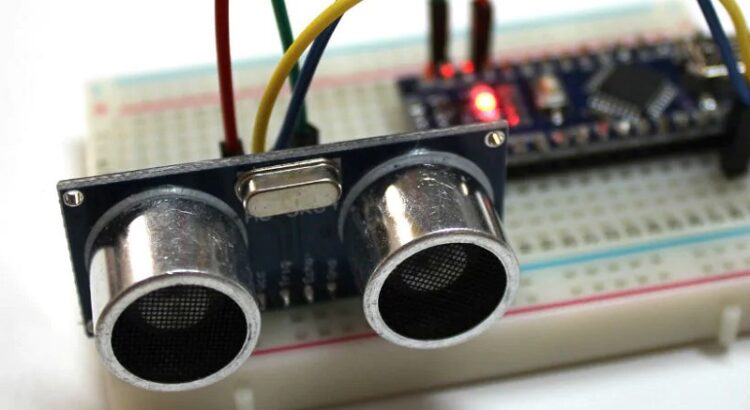

Many industries take advantage of ultrasonic sensors for level measurement. As the name suggests, ultrasonic waves use in this technology for level measurement. The head of the sensor releases ultrasonic waves and reflect them back from the target. By measuring the time taken for the emission of ultrasonic waves and their reception back, the sensor measures the level of the tank or cylinder.

A wide range of industries uses tanks for different purposes, mainly for storage and distribution purposes. Many process control areas require measuring the liquid level present inside their tank, pressure vessel, or storage vessel. These industries require innovative technology o remain the manufacturing process efficient and smart, and they can use ultrasonic sensors for that.

A non-invasive testing method

You can consider using the ultrasonic sensor of Coltraco for measuring levels of many hazardous liquids. One of the main attractions of this innovative technology is that it is capable of non-invasive testing. A technician can measure the liquid level without opening the tank for safety reasons. Besides, there is no need to install a float gauge in this method.

You can measure the liquid level without contaminating it by using an ultrasonic sensor. The storage system of the liquid does not get disturbed while using the ultrasonic sensor for the level measurement. A simple application of the tool is required to the wall of the container for measuring the liquid level. This sensor is useful to check levels without creating any safety issues for the operator or affecting his health.

Advantages of ultrasonic level measurement

Ultrasonic sensors come with many smart technologies that help to get accurate level measurements inexpensively.

- Easy to use technology

- Simple in design and construction

- Suitable for measurement in solid and liquid

- It can measure the level without contacting the processed material

- Comes with high sensitivity

- Provides better accuracy

- It can do a continuous measurement of level

With the advancement of technology, like an ultrasonic sensor, level measurement of the liquids in tanks and cylinders becomes easy. Many industries use this technology for level measurement in large tanks and cylinders. It is a fast and time-saving technology and helps industries to save labor costs. You can even find an accurate measurement of wastewater processing with the help of ultrasonic sensors.